New product launches from M.A. Ford at EMO

Several new high performance products and range extensions are planned for launch at EMO Hannover, as M.A. Ford Europe continues to expand its reach and growth across the region, particularly within Germany, Poland, Spain, Italy and France.

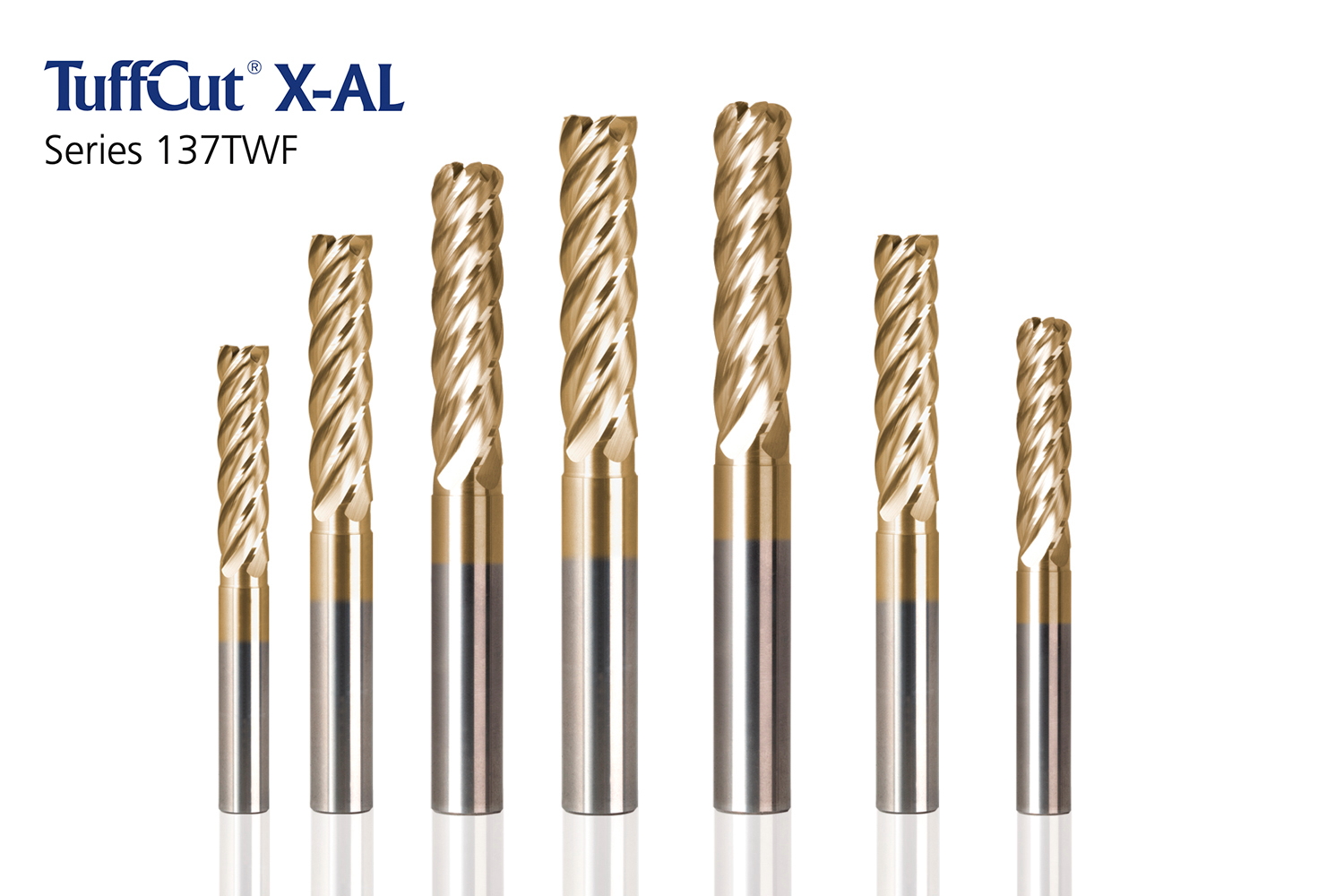

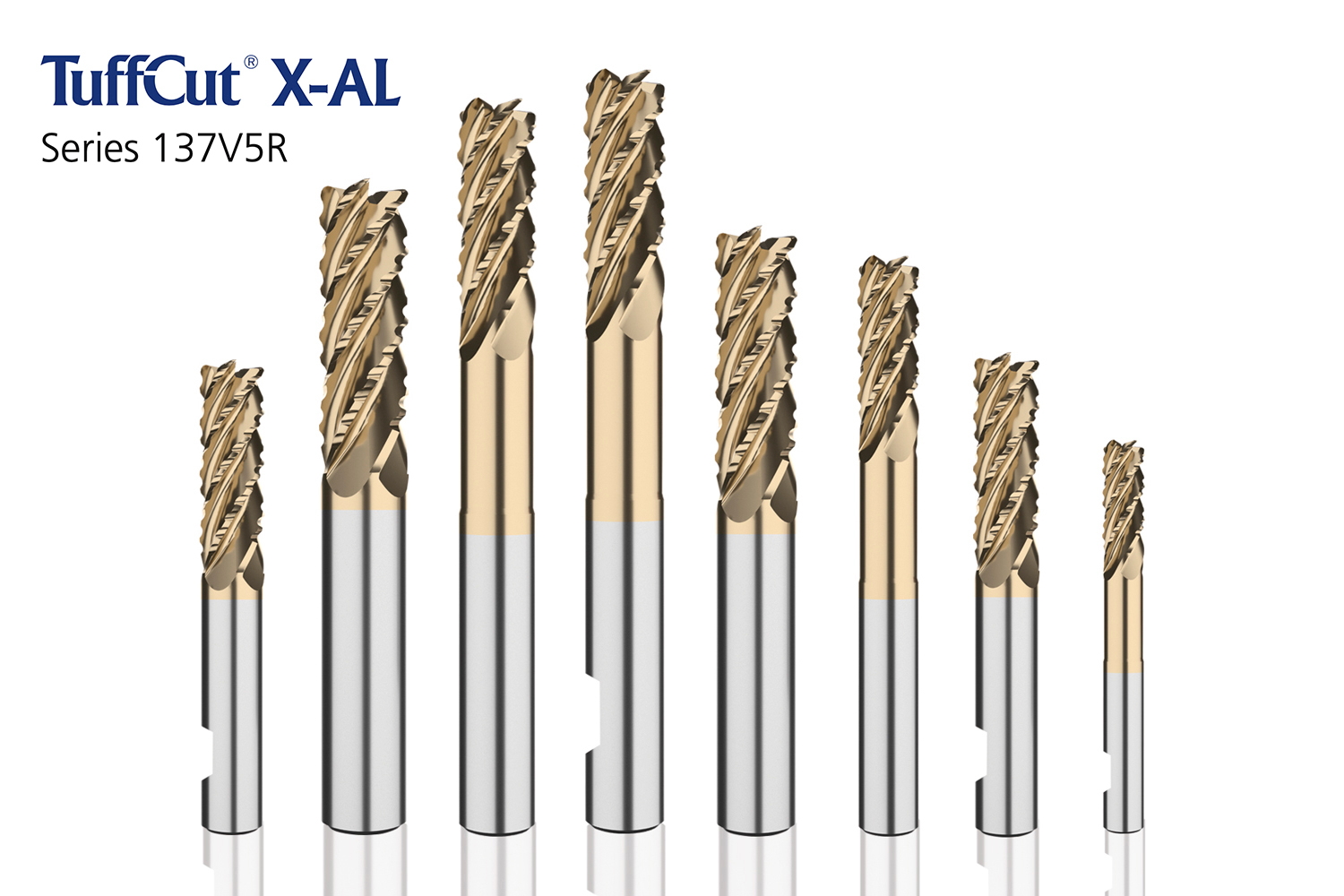

Our extensive tooling range for machining aluminium is being expanded further at EMO with the launch of two new solid carbide end mills ranges within the high performance TuffCut® X-AL family, the 5-flute Series 137TWF and Series 137V5R.

The 137TWF is designed for thin wall machining in a single pass to improve cycle times within the aerospace industry, while overcoming distortion and stepped machining issues, encountered during finishing of slender structures, such as spars and wing ribs.

With square or corner radius options and diameters from 6mm to 16mm, plus through coolant, the 137TWF also incorporates a Fordlube coating for extended tool life, making it ideal for precision finish-machining applications outside the aerospace sector.

While the new 137V5R tools share some DNA with the 137TWF, the tool design is dramatically different with aggressive chip breakers for maximum metal removal in high performance roughing applications, while reducing the power consumption, allowing it to be used on lower power machines.

The geometry also allows them to be used in finishing applications by reducing the feed rate, which can save time by removing a tool change operation. Available in HA and HB Weldon shank options and diameters of 12mm and 16mm, the 137V5R also incorporates through coolant and Fordlube coating for improved chip evacuation and tool life, while 3xD and 5xD necked flute lengths are offered within the tool series.

A new extension to the 5-flute TuffCut® XT Series 278 end mills range is also being launched at the show. The 278 3xD is designed for high performance machining of ISO P, M, S & K materials and is available in diameters from 8mm to 16mm in the HA shank option and 12mm to 16mm with the HB Weldon shank.

Two new 7-flute solid carbide end mills, the XV7 and XV7CB, incorporating staggered chip breakers, join the high performance TuffCut® XV family, which are designed for dynamic milling strategies in tough to machine materials, including titanium, high temp alloys and stainless steels. Using the latest ALtima® Q coating and variable pitch, centre cutting geometry for optimal metal removal rates, the XV7 end mills are available in 1xD; 3xD and 4xD flute lengths, with diameters ranging from 6mm to 16mm.

The new product launch list is completed with the new TrueSize® Series 275 NC machine reamers, which combine a RH spiral, and RH cutting design, with extended ‘necked’ lengths to deliver high precision and excellent hole finish quality in a wide range of materials.

Featuring h6 tolerance metric common shanks for precise tool holding, the Series 275 is available in diameters from 1.0mm to 12.0mm in 0.5mm increments, making the range an ideal solution for blind and through hole finishing.